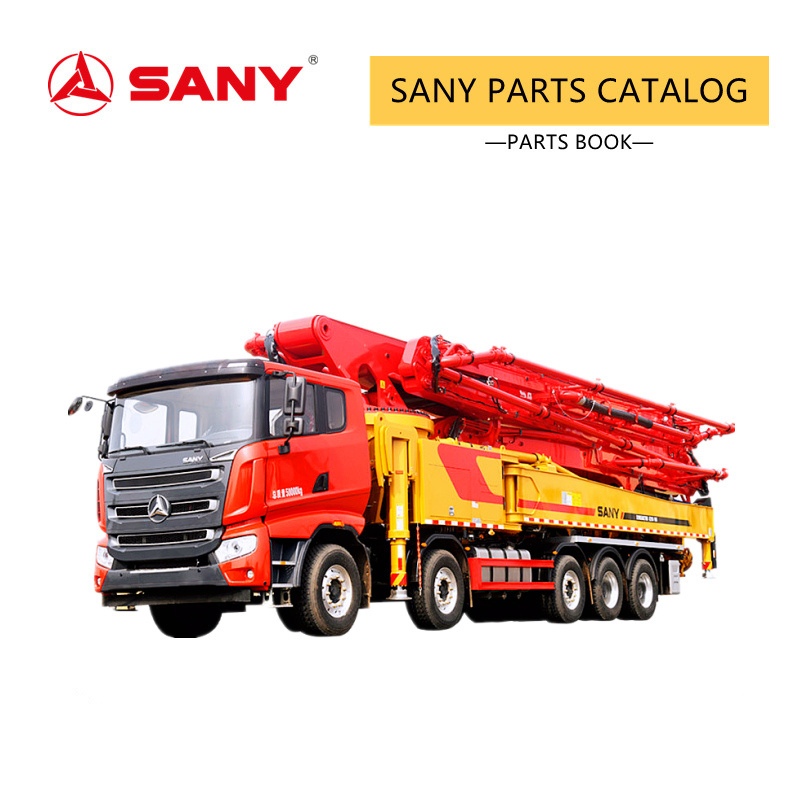

One-stop solution provider for Chinese brand heavy equipment and truck spare parts | provide professional excavator hydraulic system solutions

One-stop solution provider for Chinese brand heavy equipment and truck spare parts | provide professional excavator hydraulic system solutions